Flange Guards

Safety is paramount when working in areas that are potentially explosive and where employees may be exposed to dangerous working conditions.

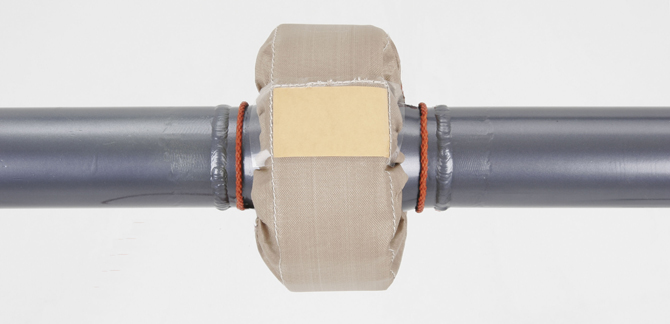

Our range of fabric and metal flange guards offer ultimate protection and prevent oil spray or dribbling caused by loose or broken pipe connections or any other source of ignition.

Porous spray guards can be used around flanges and known potential leak points, causing the material to coalesce back to a liquid and rendering it non-hazardous.

Porous spray guards can be used around flanges and known potential leak points, causing the material to coalesce back to a liquid and rendering it non-hazardous.

The Spray Guard is manufactured from three layers of woven Teflon® coated fibreglass fabric, with a central Teflon® liner for strength and a 100% TFE draw string and a Velcro fastener. This material is inherently resistant to Ultra-Violet radiation and includes a 'litmus' leak indicator patch contained within a clear Teflon window.

SOLAS Regulations

The IMO introduced new regulations concerning oil fuel arrangements through the SOLAS amendments. In particular, regulation 11-2 / 15.2.11 require that;

“Oil fuel lines shall be screened or otherwise suitably protected to avoid, as far as possible, oil spray or oil leakages onto hot surfaces, into machinery air intakes or other sources of ignition. The number of joints in such piping systems shall be kept to a minimum.”

This spray guard uses the most advanced technology to provide the best protection against hazardous spray-outs and guarantees safety regardless of which flange type and size the Spray Control Guard is mounted on.

The risk of a sudden gasket rupture in a flange connection is a constant threat to people, equipment & the environment.

The Spray Contol Guard is successfully used on practically every flange configuration; round, oval, or square forms. The flexible net adapts itself to the gap even with different gaps (or no gaps) between the flanges.

Model Code of Safe Practice IP15

The Model Code of Safe Practice IP15 (Energy Institute 3rd Edition) is an internationally accepted code for the classification of hazardous areas in the petroleum industry. It highlights a number of important issues relating to category C / class lll (1) fluids such as Diesel, Gas oil & Heating oil.

Flammable atmospheres may be formed when flammable fluids (below their flash points) are released in the form of a mist or spray. Such fluids normally regarded as non-hazardous, should be treated as hazardous when they are pumped or under pressure and are capable of producing a mist of spray if released from a small hole or flange leak.

IP15 : Item 1.3.3

...In such circumstances, therefore, those materials classified as Class lll (1) (non-hazardous) should be classed as lll (2) Hazardous.

A1.3

Need to manage small leaks and oil spray?

We provide woven Teflon and metal flange guards.

Call us on +44 (0)1785 760555 for more information