Wood Processing

Thermal fluid for wood manufacturing

The construction industry requires a variety of engineered materials for house building and other applications, such as plywood, panelling, oriented strand board (OSB) and medium density fibreboard (MDF). The process of wood manufacturing requires enormous quantities of heat, so heat transfer fluids play an important role.

Application

Globaltherm® J Heat transfer fluid is a superior high performance, energy efficient heat transfer fluid suitable for use in all kinds of industrial processes.

About Globaltherm® J

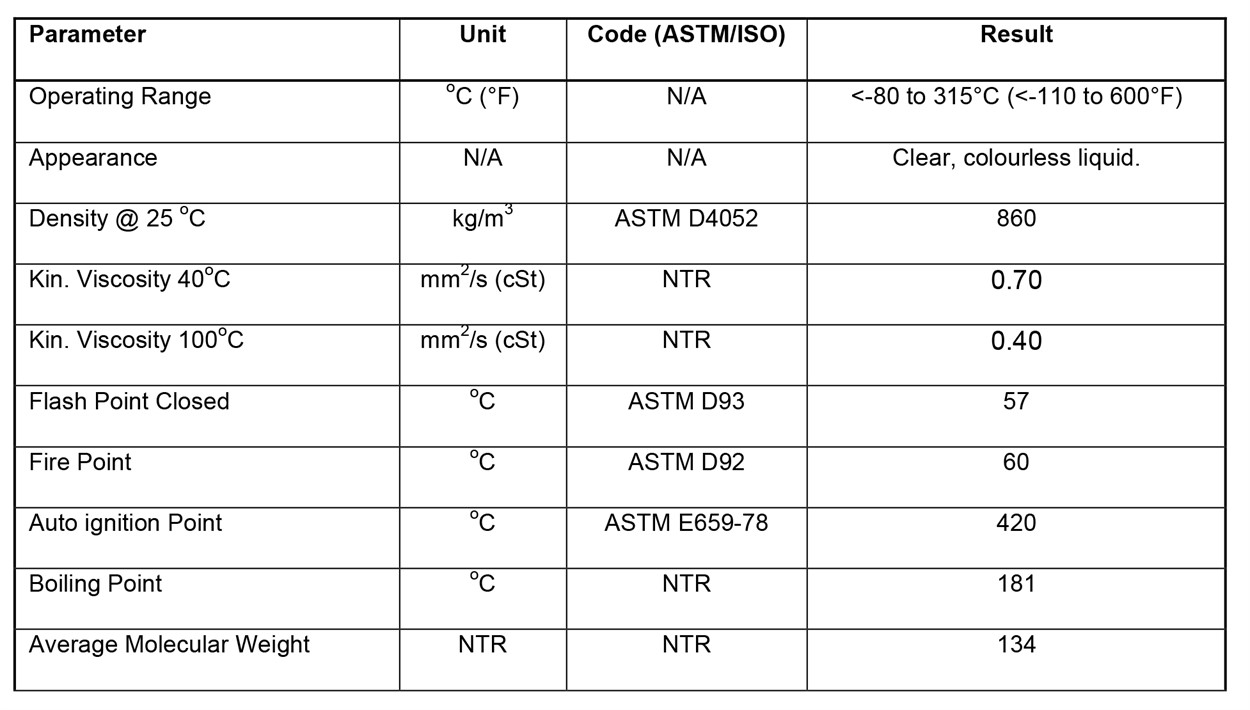

This high performance heat transfer fluid is a mixture of isomers of an alkylated aromatic specially engineered for demanding low-temperature applications in liquid phase pressurised systems.

Globaltherm® J Heat transfer fluid is a heat transfer agent suitable for applications requiring single fluid heating and cooling.

This fluid is recommended for use in a temperature range from <-80°C (-112°F) up to a maximum bulk temperature of 315°C (600°F) in the liquid phase.

This heat transfer fluid can also be used in vapour phase systems operating from 181°C to 315°C (358°F - 600°F).

This heat transfer fluid offers outstanding low-temperature pumpability and excellent thermal stability for protection against accidental overheating.

Scroll for more details

| Product | 176kg barrel |

| Globaltherm® J (-80°C – 315°C) |

|

Contact us for more information on high temperature thermal oils

We provide advice on how to choose the most appropriate oil for your heat transfer applications and provide our customers with continued technical support.

Call us on +44 (0)1785 760555 for more information

Application

A superior high performance energy efficient heat transfer fluid suitable for use in all kinds of industrial processes.

About Globaltherm® M

Made from highly refined base stocks, Globaltherm® M thermal fluid has excellent thermal and oxidation stability allowing operation at high temperatures for extended periods.

The fluid also has efficient thermal conductivity and low viscosity, at the relevant operating temperatures, ensure high heat transfer rates requiring limited pumping energy.

Globaltherm® M heat transfer fluid provides:

low vapour pressures at elevated temperatures

greatly reduced evaporation

vapour lock and cavitation eliminating the need for high pressure piping and equipment

Used fluid may be disposed of through a number of environmentally acceptable methods such as used oil recycling or heavy fuels burning.

Scroll for more details

| Parameter | Unit | Code (ASTM / ISO) | Result |

|---|---|---|---|

| Operating Range | °C (°F) | N/A | -10 to 320 (14 to 608) |

| Appearance | N/A | N/A | Viscous clear-yellow liquid with a mild odour. |

| Density @ 25°C | kg/m³ | ASTM D4052 | 873 |

| Kin. Viscosity 40°C | mm²/s (cSt) | ASTM D445 | 29.8 |

| Kin. Viscosity 100°C | mm²/s (cSt) | ASTM D445 | 4.5 |

| Flash Point PMC | °C | ASTM D93 | 210 |

| Flash Point COC | °C | ASTM D92 | 230 |

| Coefficient of Thermal Expansion | °C | NTR | 0.00077/°C |

| Autoignition Point | °C | ASTM E659 | 360 |

| Pour Point | °C | ISO 3016 | -12 |

| Neutralisation Nr (acid), TAN | mgKOH/g | ASTM D974 | <0.05 |

| Maximum Bulk Temperature | °C | NTR | 320 |

| Maximum Film Temperature | °C | NTR | 340 |

| Boiling Point at 1013 mbar | °C | NTR | 365 |

| Average Molecular Weight | NTR | NTR | 400 |

| Moisture Content | PPM | ASTM D6304 | <100 |

| Parameter | Unit | Code (ASTM / ISO) | Result |

|---|---|---|---|

| Operating Range | °C (°F) | N/A | -10 to 320 (14 to 608) |

| Appearance | N/A | N/A | Viscous clear-yellow liquid with a mild odour. |

| Density @ 25°C | kg/m³ | ASTM D4052 | 873 |

| Kin. Viscosity 40°C | mm²/s (cSt) | ASTM D445 | 29.8 |

| Kin. Viscosity 100°C | mm²/s (cSt) | ASTM D445 | 4.5 |

| Flash Point PMC | °C | ASTM D93 | 210 |

| Flash Point COC | °C | ASTM D92 | 230 |

| Coefficient of Thermal Expansion | °C | NTR | 0.00077/°C |

| Autoignition Point | °C | ASTM E659 | 360 |

| Pour Point | °C | ISO 3016 | -12 |

| Neutralisation Nr (acid), TAN | mgKOH/g | ASTM D974 | <0.05 |

| Maximum Bulk Temperature | °C | NTR | 320 |

| Maximum Film Temperature | °C | NTR | 340 |

| Boiling Point at 1013 mbar | °C | NTR | 365 |

| Average Molecular Weight | NTR | NTR | 400 |

| Moisture Content | PPM | ASTM D6304 | <100 |

Scroll for more details

| Product | 208 Litre barrel | Bulk | 25 Litre | 1050 Litre IBC |

| Globaltherm® M (-10°C – 320°C) |

|

|

|

|

Contact us for more information on high temperature thermal oils

We provide advice on how to choose the most appropriate oil for your heat transfer applications and provide our customers with continued technical support.

Call us on +44 (0)1785 760555 for more information

Using Globaltherm® MXT

- Globaltherm® MXT Heat transfer oil contains a highly resilient blend of additives resistant to sludging and ensures long-lasting and trouble-free service when managed correctly

- This heat transfer oil is a mineral based liquid phase heat transfer oil used for operating at bulk temperatures between -7°C and 320°C in both open and closed circulation.

- Globaltherm® MXT heat transfer oil is resistant to the oxidation and thermal cracking found in many industrial processing environments, including; chemical, pharmaceutical, plastics, paper, wood and textiles.

- Globaltherm® MXT Heat transfer oil is non-toxic and non-corrosive.

- This Heat transfer oil is suitable for a range of indirect open and closed liquid phase industrial heat transfer systems.

- Used oil may be disposed of through a number of environmentally acceptable methods such as used oil recycling or heavy fuels burning.

Talk to us about our all-inclusive reprocessing services.

Scroll for more details

| Product |

| Globaltherm® MXT (-7°C – 320°C) |

Contact us for more information on high temperature thermal oils

We provide advice on how to choose the most appropriate oil for your heat transfer applications and provide our customers with continued technical support.

Call us on +44 (0)1785 760555 for more information

MDF and other forms of engineered wood are processed by breaking down hardwood and softwood into wood fibres. These fibres are then bonded with wax and resin adhesives and formed into mats.

The mat is then compressed into strips and heated to extreme temperatures by a heat transfer system. The heat activation from very high temperatures generated in the system cures the wood and adhesives, creating the wood-based products.

Wood manufacturing requires enormous heat loads and a fluid that can operate at high temperatures for long periods at a time. You must prioritise safety, maintenance and output to improve uptime and increase employee safety. Heat transfer fluids are safer in these applications because they offer the precise temperature control, thermal stability and efficiency required in these large applications.

Industrial heating in wood manufacturing requires a heat transfer fluid that can work at specific temperatures for prolonged periods of time. When choosing a heat transfer fluid, you should consider temperature range and thermal stability to determine if the fluid will ensure safe and efficient operation in large applications.

The Dangerous Substances and Explosive Atmospheres Regulations (DSEAR) and the ATEX Directive must be adhered to by anyone that uses heat transfer fluids. These regulations instruct employers to carry out regular assessments on the fire and explosion risk of any work activities involving dangerous substances, including thermal fluid and synthetics.

Manufacturers should ensure that risk is managed, their site is always safe, and staff are knowledgeable on operating heat transfer systems in order to comply with DSEAR and provide a safe working environment for all employees.

Global Heat Transfer has worked with engineers in the wood manufacturing sector for over 25 years to understand what fluids best suit these applications.

All thermal fluids will degrade over time because they operate at such high temperatures. At these operating temperatures, the bonds that exist between hydrocarbon chains will start to break and form shorter (commonly referred to as ‘light-ends’) and longer chained hydrocarbons (‘heavy-ends’).

The build-up of light-end components is a potential fire risk because they decrease the ignition temperature of the HTF. The accumulation of heavy ends results in the formation of sticky carbon deposits or sludge and can be monitored by analysing the carbon residue levels in a system operating with thermal fluid.

Without proactive fluid sampling, there can also be a carbon or acid build up in the system, which can lead to a lack of flow or hotspots. Carbon is a natural insulator, so you can encounter problems with uneven heat transfer that impacts production efficiency and increases energy costs.

Continual fluid sampling and monitoring of the fluid can help to extend its lifespan. Maintenance engineers should take a hot, closed sample of the fluid to ensure it can give a representative view of what is happening to the fluid inside the system.

Manufacturers should implement a preventative maintenance programme to extend fluid life and prevent downtime. As well as regular sampling, manufacturers should complete visual checks of the system itself to ensure the equipment is operating safely and efficiently.

After taking a correct sample, the engineers at Global Heat Transfer can interpret the data to understand the condition of the fluid and if any interventions are required to improve the condition of the fluid.

Most thermal fluid companies offer a seven-point test to determine the overall condition of the fluid, but we offer more extensive analysis. Our eleven-point test looks at the sample in greater detail to ensure the results completely reflect reality.

We can help you create the right programme for your facility. As a part of Thermocare, our condition based thermal fluid lifecycle maintenance programme, our experts will work with you to improve accuracy when monitoring fluid, train staff on effective maintenance and organise maintenance schedules.

Our engineers can also provide support on-site and on the phone to help maintain production and keep the system running.

Have you got any more questions about thermal fluid for wood manufacturing?

We have over 25 years of experience in providing high quality heat transfer fluid and supporting system designers, plant managers and maintenance engineers in wood manufacturing.

Call us on +44 (0)1785 760555 for more information

Want to review our case studies in Wood Processing applications?