Pharmaceutical Processing

Heat Transfer Fluid for Pharmaceutical Processing

Pharmaceutical processing requires the use of a specific heat transfer fluid that is designed to work to the correct temperature for prolonged periods. Choosing the correct fluid can positively impact the operating efficiency of your system and increase the lifespan of both the fluid and the system.

Application

Globaltherm® L is a multi-purpose high performance benzyltoluene heat transfer fluid. It is for use in closed loop heat transfer systems. It is used predominantly in pharmaceutical industries and plastic processing and can be used in liquid and vapour form.

About Globaltherm® L

Globaltherm® L benzyltoluene HTF is recommended for use in the temperature range from -30°C (-22°F) to 360°C (680°F), but can be used intermittently at film temperatures as high as 380°C (716° F). It can also be used in pressurised systems up to 360°C (680°F).

Multi-purpose HTF in bulk outlet temperature ranges:

-20°C (-4°F) to 280°C (536°F) in non-pressurised heat transfer systems

280°C (536°F) to 680°C (680°F) in pressurised or liquid-vapour heat transfer systems

Globaltherm® L heat transfer fluid is non-corrosive

Globaltherm® L can be used in the liquid or liquid/vapour phase due to its narrow boiling range of around 4°C (39°F)

This heat transfer fluid has low pour point and pumping limit

-30°C (-22°F)

A thermal fluid with low viscosity for excellent heat transfer efficiency

Globaltherm® L is a benzyl aromatic with excellent thermal stability

Scroll for more details

| Product | 200kg barrel |

| Globaltherm® L (-30°C – 360°C) |

|

Contact us for more information on high temperature thermal oils

We provide advice on how to choose the most appropriate oil for your heat transfer applications and provide our customers with continued technical support.

Call us on +44 (0)1785 760555 for more information

Application

GLOBALTHERM® D Heat transfer fluid is a synthetic organic heat transfer fluid designed for relatively low-temperature use in the liquid phase in closed unpressurised heat transfer systems with forced circulation. The recommended upper temperature limit is 200°C.

This thermal fluid meets the FOA Regulation CFR 21 Part 178.3530 and 178.3650 and is primarily used in chemical processing applications.

About Globaltherm® D

Globaltherm® D is recommended for use in heat transfer fluid systems operating in the temperature range from -80°C (-112°F) to 200°C (392° F).

The product is most suitable for indirect cooling in refrigeration plants and in processes

GLOBALTHERM® D Heat transfer fluid is thermally stable over the recommended usage range and provides good performance

GLOBALTHERM® D Heat transfer fluid is intended for use as heat-transfer medium in a closed plant.

This heat transfer fluid does not corrode metallic materials used in the construction of heat transfer systems.

This heat transfer fluid is a non-corrosive clear heat transfer fluid

Contact us for more information on high temperature thermal oils

We provide advice on how to choose the most appropriate oil for your heat transfer applications and provide our customers with continued technical support.

Call us on +44 (0)1785 760555 for more information

Application

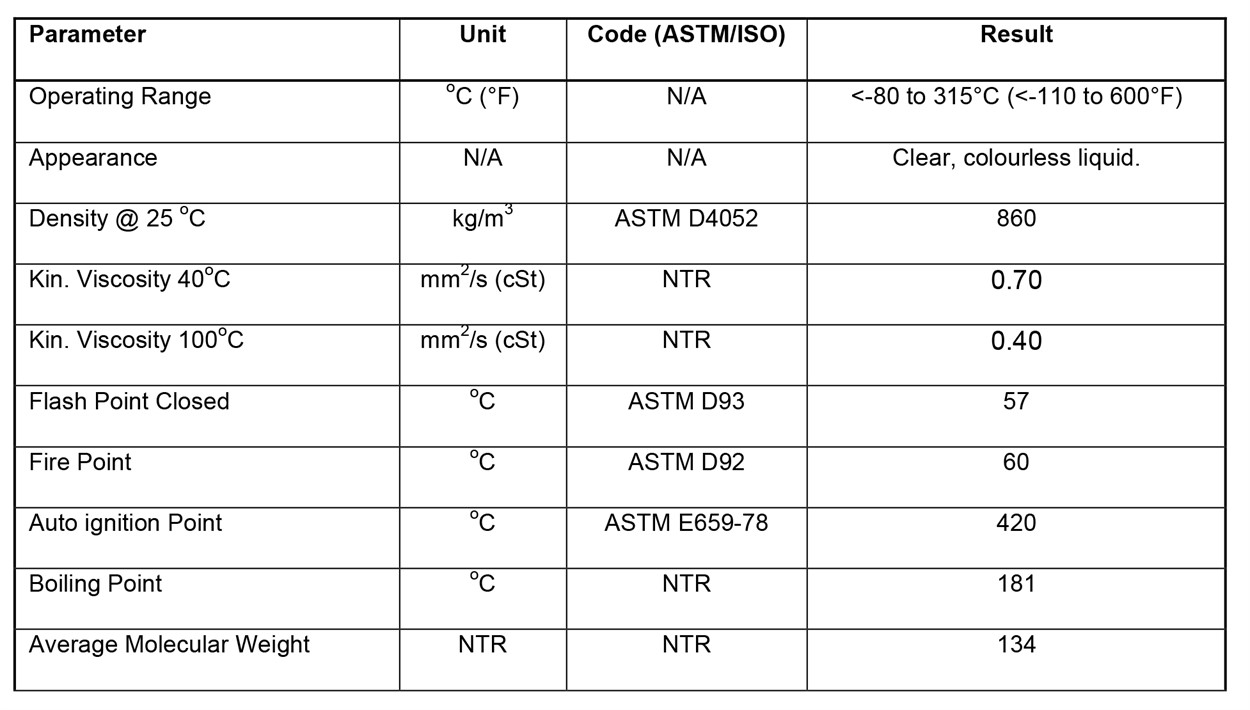

Globaltherm® J Heat transfer fluid is a superior high performance, energy efficient heat transfer fluid suitable for use in all kinds of industrial processes.

About Globaltherm® J

This high performance heat transfer fluid is a mixture of isomers of an alkylated aromatic specially engineered for demanding low-temperature applications in liquid phase pressurised systems.

Globaltherm® J Heat transfer fluid is a heat transfer agent suitable for applications requiring single fluid heating and cooling.

This fluid is recommended for use in a temperature range from <-80°C (-112°F) up to a maximum bulk temperature of 315°C (600°F) in the liquid phase.

This heat transfer fluid can also be used in vapour phase systems operating from 181°C to 315°C (358°F - 600°F).

This heat transfer fluid offers outstanding low-temperature pumpability and excellent thermal stability for protection against accidental overheating.

Scroll for more details

| Product | 176kg barrel |

| Globaltherm® J (-80°C – 315°C) |

|

Contact us for more information on high temperature thermal oils

We provide advice on how to choose the most appropriate oil for your heat transfer applications and provide our customers with continued technical support.

Call us on +44 (0)1785 760555 for more information

Application

Globaltherm® S is a high performance heat transfer fluid for use in closed loop, non-pressurised heat transfer systems. Primary uses are chemical industries and plastic processing applications.

About Globaltherm® S

Globaltherm® S is recommended for use in an upper temperature range from 250°C (482°F) to 350°C (662°F), but can be used intermittently at film temperatures as high as 380°C (716° F).

Globaltherm® S heat transfer fluid is non-corrosive and can be used in non-pressurised heat transfer systems

This heat transfer fluid can be used in systems requiring start-up temperatures as low as -5°C (23°F) without the need for heat tracing

Globaltherm® S thermal fluid is thermally stable up to 300°C (572°F) and can be used for several years below this temperature with no adverse impact on performance

Low viscosity 17cSt @ 40°C (104°F) with a pumping limit at -5°C (23°F)

This thermal fluid has a high ASTM D93 flash point at 200°C – the highest in class

Globaltherm® S has high thermal stress resistance in the bulk temperature range from 60°C-350°C (140°F - 662°F)

Globaltherm® S has a highly aromatic structure with a boiling point range of 385°C -395°C (725°F -743°F) - the highest in class

Scroll for more details

| Product | 214kg barrel | 25kg bag |

| Globaltherm® S (-5°C – 350°C) |

|

|

Contact us for more information on high temperature thermal oils

We provide advice on how to choose the most appropriate oil for your heat transfer applications and provide our customers with continued technical support.

Call us on +44 (0)1785 760555 for more information

Application

A highly efficient, non-toxic, food grade heat transfer fluid that is safe for incidental food contact in food processing plants and pharmaceutical facilities. Globaltherm FG is also Kosher and Halal certified.

About Globaltherm® FG

Made from severely hydro-treated base stocks, Globaltherm® FG thermal fluid has outstanding thermal oxidation stability allowing operation at high temperatures for extended periods. It is non-hazardous, non-toxic, water white and odourless.

Highly efficient non-fouling NSF HT-1, FDA and USDA-Certified food grade heat transfer fluid is specified in a broad variety of industrial process applications in addition to food processing.

Globaltherm FG is also Kosher certified and Halal certified.

Globaltherm® FG thermal fluid is a high efficiency heat transfer fluid specifically developed for non-pressurised, indirectly heated, liquid phase heat transfer systems found in food processing plants, pharmaceutical operations and other “food grade” applications that require bulk temperatures up to 326°C (619°F). FG is a mixture of exceptionally pure HT hydrocracked base oils.

Globaltherm® FG thermal fluid is non-hazardous, non-toxic and odourless which means it requires no special handling and is not considered a “controlled substance” under United States OSHA, Canadian WHMIS or other work place regulations.

Globaltherm® FG is NSF HT-1 Accredited

The fluid is USDA CFR Title 21 178.3570 Compliant

The fluid is also USFDA21 CR Compliant

Scroll for more details

| Product | 208 Litre barrel | Bulk | 25 Litre | 1050 Litre IBC |

| Globaltherm® FG (-20°C – 326°C) |

|

|

|

|

Scroll for more details

| Parameter | Unit | Code (ASTM / ISO) | Result |

|---|---|---|---|

| Operating Range | °C (°F) | N/A | -20 to 326 (-4 to 619) |

| Appearance | N/A | N/A | Colourless transparent liquid with no odour. |

| Density @ 25°C | kg/m³ | ASTM D4052 | 881 |

| Kin. Viscosity 40°C | mm²/s (cSt) | ASTM D445 | 29.8 |

| Kin. Viscosity 100°C | mm²/s (cSt) | ASTM D445 | 5.2 |

| Flash Point PMC | °C | ASTM D93 | 210 |

| Flash Point COC | °C | ASTM D92 | 216 |

| Coefficient of Thermal Expansion | °C | NTR | 0.00089/°C |

| Autoignition Point | °C | ASTM E659 | 350 |

| Pour Point | °C | ISO 3016 | -29 |

| Neutralisation Nr (acid), TAN | mgKOH/g | ASTM D974 | NTR |

| Maximum Bulk Temperature | °C | NTR | 326 |

| Maximum Film Temperature | °C | NTR | 343 |

| Boiling Point at 1013 mbar | °C | NTR | 371 |

| Average Molecular weight | NTR | NTR | 350 |

| Moisture Content | PPM | ASTM D6304 | <100 |

| Parameter | Unit | Code (ASTM / ISO) | Result |

|---|---|---|---|

| Operating Range | °C (°F) | N/A | -20 to 326 (-4 to 619) |

| Appearance | N/A | N/A | Colourless transparent liquid with no odour. |

| Density @ 25°C | kg/m³ | ASTM D4052 | 881 |

| Kin. Viscosity 40°C | mm²/s (cSt) | ASTM D445 | 29.8 |

| Kin. Viscosity 100°C | mm²/s (cSt) | ASTM D445 | 5.2 |

| Flash Point PMC | °C | ASTM D93 | 210 |

| Flash Point COC | °C | ASTM D92 | 216 |

| Coefficient of Thermal Expansion | °C | NTR | 0.00089/°C |

| Autoignition Point | °C | ASTM E659 | 350 |

| Pour Point | °C | ISO 3016 | -29 |

| Neutralisation Nr (acid), TAN | mgKOH/g | ASTM D974 | NTR |

| Maximum Bulk Temperature | °C | NTR | 326 |

| Maximum Film Temperature | °C | NTR | 343 |

| Boiling Point at 1013 mbar | °C | NTR | 371 |

| Average Molecular weight | NTR | NTR | 350 |

| Moisture Content | PPM | ASTM D6304 | <100 |

Application

The most popular high temperature, synthetic heat transfer fluid. Suitable for operation up to 345°C (653°F) and can pumped to -3°C (27°F) and delivers exceptional performance. Primary applications are chemical industries, plastics processing and biodiesel.

About Globaltherm® Syntec

Globaltherm® Syntec uses the hydrogenated terphenyls chemistry of the most popular high temperature liquid phase heat transfer fluid. No other heat transfer fluid delivers a higher degree of customer satisfaction.

Globaltherm® Syntec HTF is used in a wide variety of applications in systems all over the world and delivers ultimate performance to ensure your system is running at maximum capacity and optimum efficiency.

Scroll for more details

| Parameter | Unit | Code (ASTM/ISO) | Result |

|---|---|---|---|

| Appearance | N/A | N/A | Clear to pale yellow liquid with a characteristic odour |

| Operating Range | °C (°F) | N/A | -3° to 345 (27 to 653) |

| Density @25°C | kg/m³ | ASTM D4052 | 1005 |

| Kin. Viscosity @40°C | mm²/s (cSt) | ASTM D445 | 29.6 |

| Kin. Viscosity @100°C | mm²/s (cSt) | ASTM D445 | 3.80 |

| Flashpoint PMC | °C (°F) | ASTM D93 | 170 (338) |

| Flashpoint COC | °C (°F) | ASTM D92 | 184 (363) |

| Coeefficient of thermal expansion | °C | NTR | 0.000819/°C |

| Autoignition point | °C (°F) | ASTM E659 | 374 (705) |

| Pour point | °C (°F) | ISO3016 | -32 (-25.6) |

| Neutralisation Nr (acid), TAN | Mg KOH/g | ASTM D664 | <0.2 |

| Maximum Bulk Temperature | °C (°F) | NTR | 345 (653) |

| Maximum film temperature | °C (°F) | NTR | 375 (707) |

| Boiling point at mbar | °C (°F) | NTR | 359 (678) |

| Average molecular weight | NTR | NTR | 252 (485.6) |

| Moisture content | PPM | ASTM E-203 | 150 ppm |

| Parameter | Unit | Code (ASTM/ISO) | Result |

|---|---|---|---|

| Appearance | N/A | N/A | Clear to pale yellow liquid with a characteristic odour |

| Operating Range | °C (°F) | N/A | -3° to 345 (27 to 653) |

| Density @25°C | kg/m³ | ASTM D4052 | 1005 |

| Kin. Viscosity @40°C | mm²/s (cSt) | ASTM D445 | 29.6 |

| Kin. Viscosity @100°C | mm²/s (cSt) | ASTM D445 | 3.80 |

| Flashpoint PMC | °C (°F) | ASTM D93 | 170 (338) |

| Flashpoint COC | °C (°F) | ASTM D92 | 184 (363) |

| Coeefficient of thermal expansion | °C | NTR | 0.000819/°C |

| Autoignition point | °C (°F) | ASTM E659 | 374 (705) |

| Pour point | °C (°F) | ISO3016 | -32 (-25.6) |

| Neutralisation Nr (acid), TAN | Mg KOH/g | ASTM D664 | <0.2 |

| Maximum Bulk Temperature | °C (°F) | NTR | 345 (653) |

| Maximum film temperature | °C (°F) | NTR | 375 (707) |

| Boiling point at mbar | °C (°F) | NTR | 359 (678) |

| Average molecular weight | NTR | NTR | 252 (485.6) |

| Moisture content | PPM | ASTM E-203 | 150 ppm |

Note: The information given in the typical data does not constitute a specification but is an indication based on current production and can be affected by allowable production tolerances. The right to make modifications is reserved. This edition supersedes all previous editions and information contained within them. Typical values should not be construed as a guaranteed analysis of any specific lot or as specifications for the product. Abbreviations: OC, open cup test; COC, Cleveland open cup test; and, NTR, no test reported.

Scroll for more details

| Product | 200kg barrel | Bulk | 1000kg IBC | 25kg drum |

| Globaltherm® Syntec (-3°C – 345°C) |

|

|

|

|

Contact us for more information on high temperature synthetic thermal oils

We provide advice on how to choose the most appropriate oil for your heat transfer applications and provide our customers with continued technical support.

Call us on +44 (0)1785 760555 for more information

Application

Globaltherm® C is an organic stress resistant heat transfer fluid for use in the liquid or vapour phase in closed heat transfer systems with forced circulation.

About Globaltherm® C

Globaltherm® C can be used in heat transfer systems for use as a liquid in non-pressurised systems from -90°C (-130°F) to 153°C (307°F) and in pressurised systems up to 300°C (572°F).

This thermal fluid is for use in multi-purpose heat transfer systems where heating and cooling loops must be operated simultaneously

Globaltherm® C is thermally stable up to 300°C (572°F) and particularly suitable in applications where exposure to air cannot be completely prevented

This product provides turbulent flow and efficient heat transfer to -90°C (-112°F)

Globaltherm® C can be used in systems requiring low start-up temperatures from -90°C (-130°F) without the need for heat tracing

Globaltherm® C operates effectively in non-pressurised systems in the range -90°C - 180°C (-112°F - 356°F)

This heat transfer fluid is non-corrosive.

Scroll for more details

| Product | 177kg barrel |

| Globaltherm® C (-90°C – 300°C) |

|

Contact us for more information on high temperature thermal oils

We provide advice on how to choose the most appropriate oil for your heat transfer applications and provide our customers with continued technical support.

Call us on +44 (0)1785 760555 for more information

In pharmaceutical processing, some chemical reactions take place at very high temperatures, and others, such as crystallisation, require low temperatures. To accommodate all the required processes, heat transfer fluids used in pharmaceutical processing must have a broad operating temperature range.

Chemical composition is an important factor to consider when selecting a heat transfer fluid. Chemical composition will have an impact on the fluid’s properties, such as thermal stability and heat transfer efficiency. Matching the fluid to the system and the operating temperature can help to preserve fluid life.

While mineral heat transfer oils offer a good trade off between cost and performance, synthetic heat transfer fluids are the more popular choice in pharmaceutical applications. These have a lower susceptibility to form carbon than mineral based oils, offer better heat transfer efficiency and thermal stability, as well as a higher resistance to fouling.

Global Heat Transfer has over 30 years of experience in supplying and maintaining thermal fluid for the pharmaceutical industry.

A range of Globaltherm® heat transfer fluids can be used for pharmaceutical batch processing because of their broad operating temperature range.

Proactive analysis and maintenance of heat transfer fluid is essential for pharmaceutical manufacturers. Thermal fluids degrade over time, particularly at high temperatures, reducing the efficiency of the system.

Regular thermal fluid analysis helps plant managers monitor oil condition. By taking a sample when the heat transfer system is hot, closed and circulating, plant managers get an accurate representation of the condition of the fluid inside the system.

After taking an accurate sample, plant managers can send the sample to thermal fluid experts, such as Global Heat Transfer, for analysis. Regular sampling can also act as an early warning system, allowing plant managers to intervene and solve issues before they impact production.

At Global Heat Transfer we provide an extensive preventative maintenance programme, Thermocare.

Our expert engineers will work with you to improve accuracy when monitoring fluid, provide technical interventions when necessary, organise maintenance schedules and train staff. Our team also offers 24 hour engineering support to help you quickly diagnose and fix faults that can impact production.

Need more advice on choosing and maintaining thermal fluids?

For more personal advice on heat transfer fluid choice and maintenance in your application, call our technical team on 01785 760 555 or visit our contact page.