Solar & Thermal Storage

Heat Transfer Fluid for Concentrated Solar Power and Thermal Storage Applications

Concentrated Solar Power (CSP) plants require the use of a specific heat transfer fluid (HTF) that is designed to work to the correct temperature for prolonged periods in solar thermal electricity applications.

How does concentrated solar power work?

CSP uses reflectors to concentrate sunlight onto a receiver containing heat transfer fluid, which is heated and used to convert water to steam. The steam turns turbines, leading to electricity generation. The heat transfer fluid can also be used to store energy from the sunlight, allowing consistent power provision despite the intermittent supply of sunlight.

Application

Globaltherm® Omnitech is a high performance synthetic heat transfer fluid designed to meet the demands of liquid or vapour phase systems and indirect heat transfer. The no.1 choice for concentrated solar power and thermal electricity applications, PET and plastics production and chemical industries.

About Globaltherm® Omnitech

Globaltherm® Omnitech is a synthetic thermal fluid which combines low viscosity and exceptional thermal stability for consistent performance.

Globaltherm® Omnitech is a diphenyl ether-biphenyl HTF mixture

The eutectic mixture of diphenyl oxide and biphenylgives this heat transfer fluid flexibility to perform in both vapour and liquid phases. It is miscible and interchangeable (for top-up or dilution purposes) with other similar mix thermal fluids.

Globaltherm Omnitech HTF has low viscosity (2.5 cst at 40°C [104°F])

This thermal fluid is excellent for use in heat transfer fluid systems which require very precise temperature control due its ability to operate as a vapour phase fluid

This heat transfer fluid is highly dependable

Scroll for more details

| Parameter | Unit | Code | Result |

|---|---|---|---|

| Appearance | N/A | N/A | Clear-to-light yellow liquid with a geranium-like odour |

| Operating range | °C (°F) | 15 to 400 (59 to 752) liquid phase. 257 to 400 (495 to 752) vapour phase | |

| Vapour pressure | Psia | 152.02 | |

| Freeze Point | °C (°F) | N/A | 12°C (53.6°F) |

| Viscosity (at min. use temp) | ASTM D445 | 4.91 | |

| Viscosity (at max. use temp) | ASTM D445 | 0.13 | |

| Flash Point PMC | °C (°F) | ASTM D93 | 113 (236 °F) |

| Flash Point COC | °C | 123 | |

| Coefficient of thermal expansion | °C | 0.000979/ °C | |

| Autoignition point | °C (°F) | ASTM E659 | 599 (1110°F) |

| Pour point | °C | ISO 3016 | 11 |

| Neutralisation Nr (acid), TAN | mgKOH/g | ASTM D974 | <0.2 |

| Maximum bulk temperature | °C | NTR | 400 |

| Maximum film temperature | °C | NTR | 425 |

| Boiling point at 1013 mbar | °C (°F) | NTR | 257 |

| Average molecular weight | NTR | NTR | 166 |

| Moisture content | PPM | ASTM D6304 | <300 |

| Parameter | Unit | Code | Result |

|---|---|---|---|

| Appearance | N/A | N/A | Clear-to-light yellow liquid with a geranium-like odour |

| Operating range | °C (°F) | 15 to 400 (59 to 752) liquid phase. 257 to 400 (495 to 752) vapour phase | |

| Vapour pressure | Psia | 152.02 | |

| Freeze Point | °C (°F) | N/A | 12°C (53.6°F) |

| Viscosity (at min. use temp) | ASTM D445 | 4.91 | |

| Viscosity (at max. use temp) | ASTM D445 | 0.13 | |

| Flash Point PMC | °C (°F) | ASTM D93 | 113 (236 °F) |

| Flash Point COC | °C | 123 | |

| Coefficient of thermal expansion | °C | 0.000979/ °C | |

| Autoignition point | °C (°F) | ASTM E659 | 599 (1110°F) |

| Pour point | °C | ISO 3016 | 11 |

| Neutralisation Nr (acid), TAN | mgKOH/g | ASTM D974 | <0.2 |

| Maximum bulk temperature | °C | NTR | 400 |

| Maximum film temperature | °C | NTR | 425 |

| Boiling point at 1013 mbar | °C (°F) | NTR | 257 |

| Average molecular weight | NTR | NTR | 166 |

| Moisture content | PPM | ASTM D6304 | <300 |

Note: The information given in the typical data does not constitute a specification but is an indication based on current production and can be affected by allowable production tolerances. The right to make modifications is reserved. This edition supersedes all previous editions and information contained within them. Typical values should not be construed as a guaranteed analysis of any specific lot or as specifications for the product. Abbreviations: OC, open cup test; COC, Cleveland open cup test; and, NTR, no test reported.

Scroll for more details

| Product | 200kg barrel |

| Globaltherm® Omnitech (15°C – 400°C) |

|

Contact us for more information on high temperature thermal oils

We provide advice on how to choose the most appropriate oil for your heat transfer applications and provide our customers with continued technical support.

Call us on +44 (0)1785 760555 for more information

Application

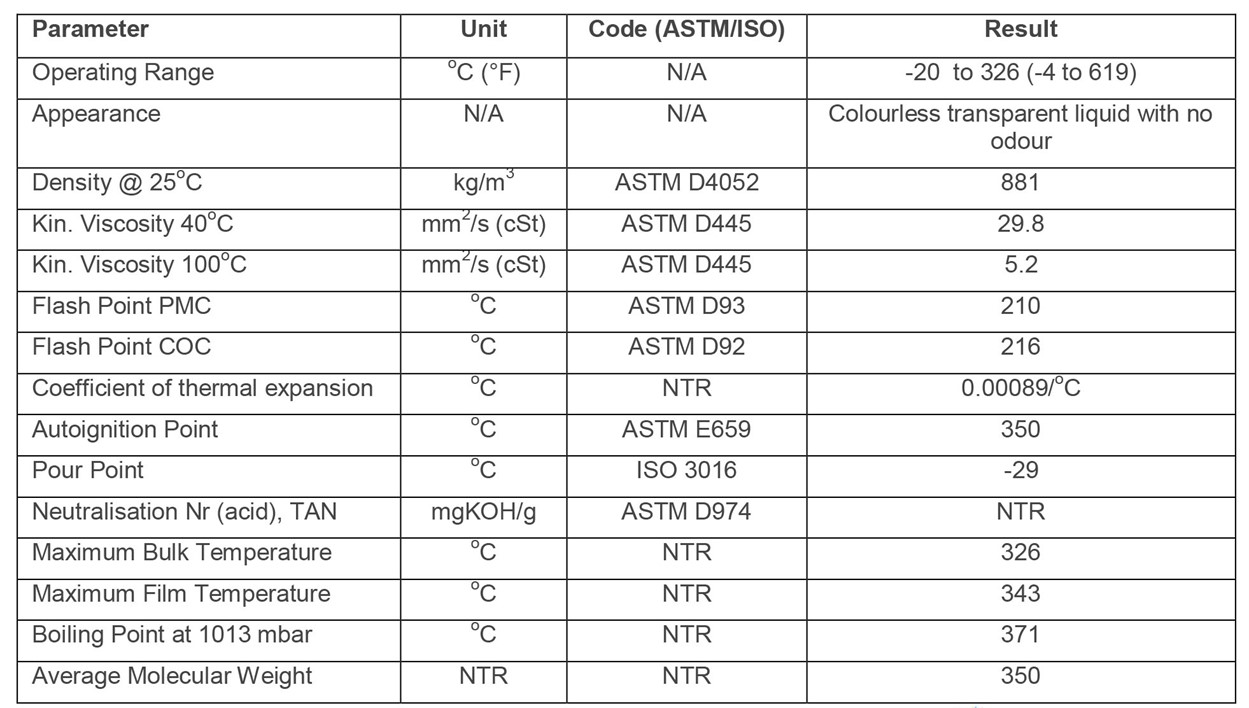

Globaltherm® Omnipure is a highly efficient non-toxic, heat transfer fluid that is designed specifically for Concentrated Solar Plant (CSP) and thermal storage applications, PET and plastics production and chemical industries.

About Globaltherm® Omnipure

This heat transfer fluid is made from highly refined mineral oil and has superior oxidation properties for optimum performance.

Globaltherm® Omnipure thermal fluid is made from severely hydro-treated base stocks and has outstanding thermal oxidation stability allowing for operation at high temperatures for extended periods.

Globaltherm® Omnipure is non-hazardous, non-toxic, water white and odourless.

This heat transfer fluid is specifically developed for non-pressurised, indirectly heated, liquid phase heat transfer systems found in Concentrated Solar Plant (CSP) and thermal storage applications that require bulk temperatures up to 326°C (619°F)

Scroll for more details

| Product | 1000 Litre IBC | 209 Litre barrel | Bulk |

| Globaltherm® Omnipure (-20°C – 326°C) |

|

|

|

Contact us for more information on high temperature thermal oils

We provide advice on how to choose the most appropriate oil for your heat transfer applications and provide our customers with continued technical support.

Call us on +44 (0)1785 760555 for more information

Application

Non-hazardous, low toxicity, silicone based heat transfer fluid. Globaltherm® Omnisol is the high temperature silicone based thermal fluid for Concentrated Solar Power (CSP) thermal storage applications.

About Globaltherm® Omnisol

Globaltherm® Omnisol – is a silicone based heat transfer media used in solar thermal storage applications at high temperatures.

Omnisol can safely withstand temperatures up to 425°C (797°F).

Globaltherm® Omnisol delivers the high thermal stability and reliable heat transfer of a polydimethylsiloxane mixture with a low pumpability point of -65°C (-85°F). Globaltherm ® Omnisol is a high performing low toxicity, low fire risk, heat transfer fluid for CSP applications operating up to 425°C (797°F).

Globaltherm® Omnisol is suitable for use in parabolic trough applications requiring a low freeze point and low temperature pumpability.

Scroll for more details

| Product | 1000 Litre IBC | 200kg barrel | Bulk |

| Globaltherm® Omnisol (-65°C – 425°C) |

|

|

|

Contact us for more information on high temperature thermal oils

We provide advice on how to choose the most appropriate oil for your heat transfer applications and provide our customers with continued technical support.

Call us on +44 (0)1785 760555 for more information

Application

Non-toxic and non-flammable heat transfer media. Globaltherm® Omnistore MS-600 is the high temperature heat transfer media for Concentrated Solar Power (CSP) and thermal electricity storage applications.

About Globaltherm® Omnistore MS-600

Globaltherm® Omnistore MS-600 – is a molten salt heat transfer media used in solar thermal storage applications at very high temperatures.

Omnistore MS-600 can safely withstand temperatures up to 600°C (1076°F), higher than most heat transfer media on the market today.

Globaltherm® Omnistore MS-600 molten salt heat transfer media has excellent thermo-physical properties in the liquid state, such as low viscosity, high heat capacity, and high thermal conductivity. Globaltherm’s heat transfer molten salts provide long-term heat storage for high-temperature applications.

Globaltherm® Omnistore MS-600 minimises safety hazards and the need for high-pressure equipment.

Scroll for more details

| Product | Bulk |

| Globaltherm® Omnistore MS-600 (149°C – 600°C) |

|

Contact us for more information on high temperature thermal oils

We provide advice on how to choose the most appropriate oil for your heat transfer applications and provide our customers with continued technical support.

Call us on +44 (0)1785 760555 for more information

Application

Globaltherm® S is a high performance heat transfer fluid for use in closed loop, non-pressurised heat transfer systems. Primary uses are chemical industries and plastic processing applications.

About Globaltherm® S

Globaltherm® S is recommended for use in an upper temperature range from 250°C (482°F) to 350°C (662°F), but can be used intermittently at film temperatures as high as 380°C (716° F).

Globaltherm® S heat transfer fluid is non-corrosive and can be used in non-pressurised heat transfer systems

This heat transfer fluid can be used in systems requiring start-up temperatures as low as -5°C (23°F) without the need for heat tracing

Globaltherm® S thermal fluid is thermally stable up to 300°C (572°F) and can be used for several years below this temperature with no adverse impact on performance

Low viscosity 17cSt @ 40°C (104°F) with a pumping limit at -5°C (23°F)

This thermal fluid has a high ASTM D93 flash point at 200°C – the highest in class

Globaltherm® S has high thermal stress resistance in the bulk temperature range from 60°C-350°C (140°F - 662°F)

Globaltherm® S has a highly aromatic structure with a boiling point range of 385°C -395°C (725°F -743°F) - the highest in class

Scroll for more details

| Product | 214kg barrel | 25kg bag |

| Globaltherm® S (-5°C – 350°C) |

|

|

Contact us for more information on high temperature thermal oils

We provide advice on how to choose the most appropriate oil for your heat transfer applications and provide our customers with continued technical support.

Call us on +44 (0)1785 760555 for more information

There are four optical types of CSP system:

These are the most well developed CSP systems. They use parabolic reflectors to concentrate sunlight onto a receiver directly above the middle of the parabolic reflector. The receiver is filled with heat transfer fluid, which absorbs the thermal energy from the sunlight. The reflectors track the sun along a single axis to maximise the amount of thermal energy they pick up.

Also known as central receiver systems, solar power towers use an array of dual axis mirrors called heliostats, which track sunlight. These systems offer higher energy efficiency and better thermal energy storage capability than parabolic troughs.

These systems consist of a stand-alone parabolic reflector that concentrates sunlight onto a receiver. The reflector tracks the sun along two axes and the system uses a Stirling Engine to generate power.

These systems are made of multiple thin, flat reflectors that concentrate sunlight onto tubes through which heat transfer fluid is pumped.

Globaltherm® has a range of heat transfer fluids designed for use in CSP applications. They work at precise temperatures for prolonged periods of time. The range is highly efficient and each product has different qualities to suit a range of applications. These fluids also have superior anti-oxidation properties for optimum performance.

All heat transfers will degrade over time and engineers should monitor the degradation process to ensure that it does not impact production. When operated at a high temperature for long periods of time the fluid will begin to break down.

When the bonds between of hydrocarbon chains break, this produces short-chained “light ends”. The higher the operating temperature, the more light ends are generated, and the rate at which they are produced is dependent on the oil type and the operating temperature.

Light ends boil and ignite at lower temperatures and reduce the flash point of thermal fluid. This creates a fire hazard and companies have a duty to manage this in line with the Dangerous Substances and Explosive Atmospheres Regulations (DSEAR) as well as with the explosive atmosphere (ATEX) regulations. Light ends also lead to cavitation in thermal fluid system pumps, which can lead to operational problems. When light ends are generated, both system and workforce safety are severely compromised.

The heat transfer fluid cannot be seen when circulating inside the system, so it is difficult to monitor its condition. Implementing regular thermal fluid testing and analysis is the best way to understand what is happening inside the system.

Global Heat Transfer’s flash point management service includes two flash point tests. Engineers will do an open test to test the fluid when it comes into contact with oxygen and a closed test when the fluid is contained in the system.

If sample analysis shows that the flash point temperature has dropped then it is highly likely that there are light-ends contained in the fluid.

Light-ends removal kits for thermal fluid regeneration are specifically designed to manage the flash point by removing volatile light ends from a heat transfer system. The light ends removal thermal fluid regeneration kit is tailored to the heating system and the thermal oil used.

It can be used on both large and small systems, which may be open or closed, and used with both mineral and synthetic thermal fluids. It can be used for a fixed duration on a temporary basis when using the active pump-fed unit, or as a permanent installation to manage light ends on a continuous basis.

As a part of Global Heat Transfer’s preventative maintenance programme, Thermocare, manufacturers can receive 24 hour engineering support for their systems. These engineers will also take regular samples and analyse the fluid to give concentrated solar power plant managers an accurate representation of what is happening inside the system.

Where can I get more advice about choosing and monitoring heat transfer fluids for solar?

We offer a range of thermal fluids and services that will ensure your heat transfer system is always running efficiently.

For more personalised advice, call our team on +44 (0)1785 760 555 or visit our contact page.

Want to review our case studies in Solar & Thermal Storage applications?